How can we help you?

How can we help you?

Since 1930, ARO has been an industry leader in the design and manufacture of pneumatic tools and air preparation equipment.

Clean air is a key ingredient that enables the effective and efficient operation of tools, equipment, and machinery in almost every industry. Using air preparation devices, such as filters, regulators and lubricators (FRLs), is an excellent means of keeping your air supply in top condition, as well as enabling your tools and equipment to operate at their peak performance. The ARO-Flo Series FRLs continue the tradition of offering premium products for your operation, and also raises the bar in the industry for safety, flow performance, and modularity.

If you need assistance choosing the right air filter, regulator, and lubricator combination for your application or have questions regarding assembly or accessories, contact us today. Our experts are happy to help.

Providing safe tools and equipment is our top priority. Our ARO-Flo Series of filters, regulators and lubricators and select accessories can be used in hazardous duty locations requiring ATEX compliance. Learn more.

ARO-Flo Series FRLs are designed with integrated safety features such as locking bowls and clear multilingual markings. Accessories such as lockout valves, check valves, and soft-start valves allow the air supply to be safely managed and controlled.

ARO attests that ARO-Flo Series of filters, regulators, lubricators (1000, 1500, 2000, 3000 Series) and select accessories are out of scope for ATEX Directive 94/9/EEC or 2014/34/EU. Instruction Manuals and certificates regarding ATEX Declaration can be found here.

All ARO-Flo accessories are designed to integrate with each other within each size range. From pipe adapters to T-brackets, your complete FRL assembly and its individual components can be easily, safely, and quickly assembled or disassembled with a minimum of tools — no fuss or complications, even with fixed piping.

ARO-Flo Series FRLs set the standard for flow performance. Simply put, air flows better through ARO-Flo filters, regulators, and lubricators than almost any other air filtration device. This means less air is choked during the air preparation process, and your equipment can perform at its peak performance.

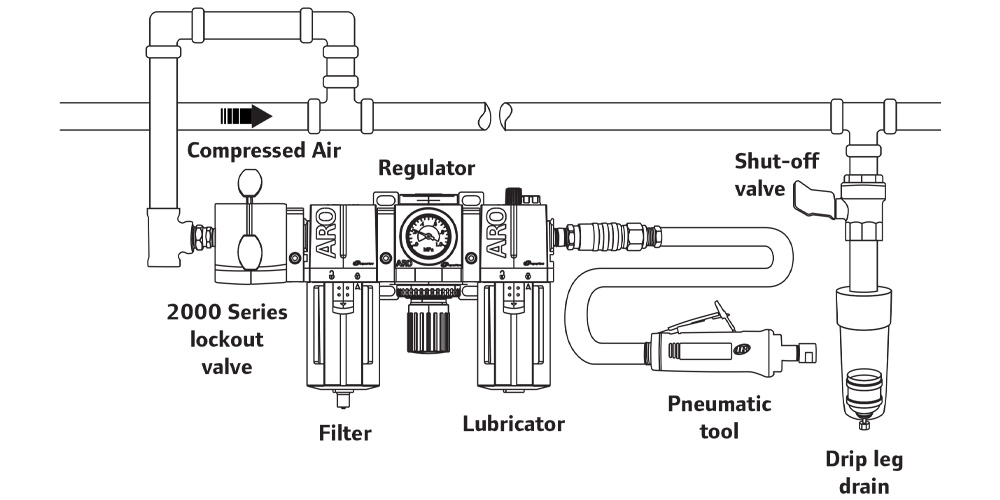

The filter, regulator and lubricator (FRL) should be installed in the order shown in the illustration below. If a coalescing filter is required, it should be installed downstream from a standard filter. Individual take-off lines to the FRL and air tool or equipment should be from the top of the compressed air line. Make sure that air flow markings are followed for proper flow direction through the FRL units.

To trap and expel water, sludge and other contaminants which may collect on the bottom of the air line, a drip leg drain should be used. Drip leg drains should be installed at low points in the piping system and at the far end of the distribution system.